N6.S BASIC

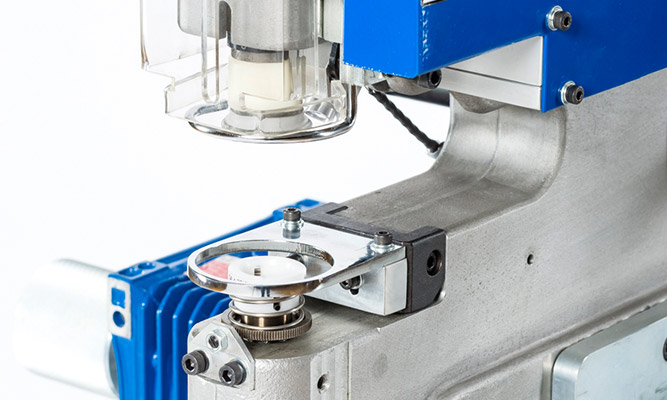

Semi-automatic attaching machine with electric drive

For processing snaps of all systems (Spring, S-Spring, FlexFix™, KNIPPER™, ISOFIX marking system), jeans buttons and clothing rivets, posts, eyelets, etc.

The items are manually inserted into the upper and lower stamp.

A spring assembly compensates for different fabric thicknesses. The articles can be attached to any type of fabric without readjusting the machine if the type of fabric and the fabric thickness are within the values specified by YKK STOCKO FASTENERS.

The machine is equipped with a movable (active) finger protection system that allows a large clearance height in the attaching area. Thanks to a particularly large projection (insertion depth), even thick material or textile structures can also be processed.

ISOFIX marking system

A modified N6-ISOFIX application machine is required for processing the ISOFIX marking system, which enables the marking to be applied in an aligned manner.

Different technical equipment applies to this machine.

Equipment

- Target device (positioning aid)

- Movable (active) finger protection system

- Automatic fabric thickness compensation (spring assembly)

- CE marking

Machine description

| Connected loads | 230 V, 50 Hz |

| Attaching capacity | 0.3 sec. / work cycle |

| Attaching pressure | 4000 N |

| Working height | 82 mm |

| Insertion depth | 145 mm |

| Diffuser height | 30 mm in the area of the finger protection system |

| Height | 1100 mm |

| Width | 510 mm |

| Depth | 450 mm |

| Weight | 60 kg |

| Triggering | Foot pedal |

| Optional accessories | Stop table |

Subject to technical changes