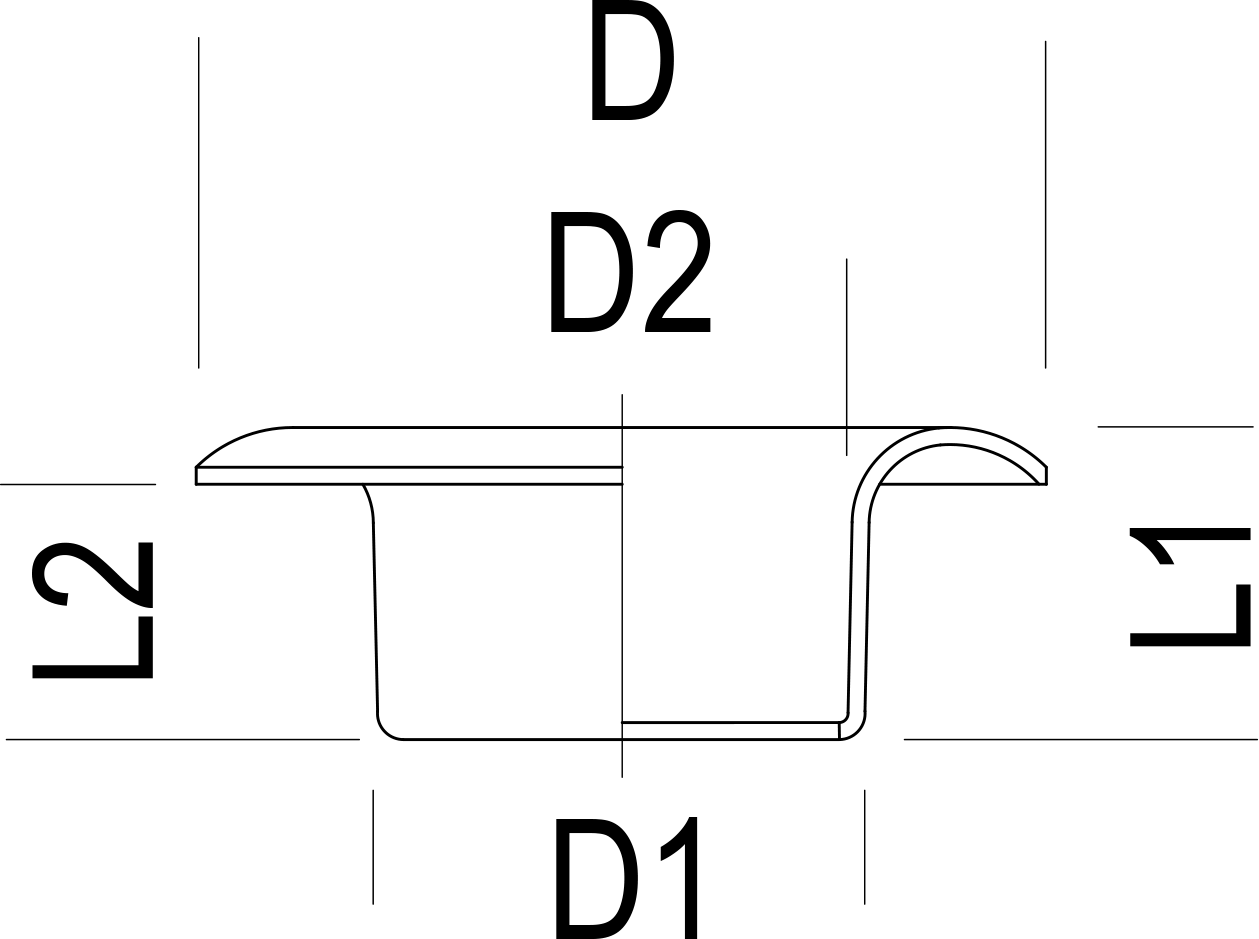

Textile eyelets, Shoe and leather goods eyelets

Material brass | stainless steel

Hole reinforcement rings for riveting

Our textile eyelets, Shoe and leather goods eyelets predominantly made of brass, in a wide range of diameters and shaft heights, are primarily suitable for reinforcing perforated holes in materials such as leather, plastics and non-elastic textiles. The eyelet is used wherever a cord is passed through or dimensions need to be varied. But the eyelet also reliably fulfills its purpose for ventilation or simply for decorative purposes.

Discover article S 5S, our stainless steel textile eyelet.