WetStop®

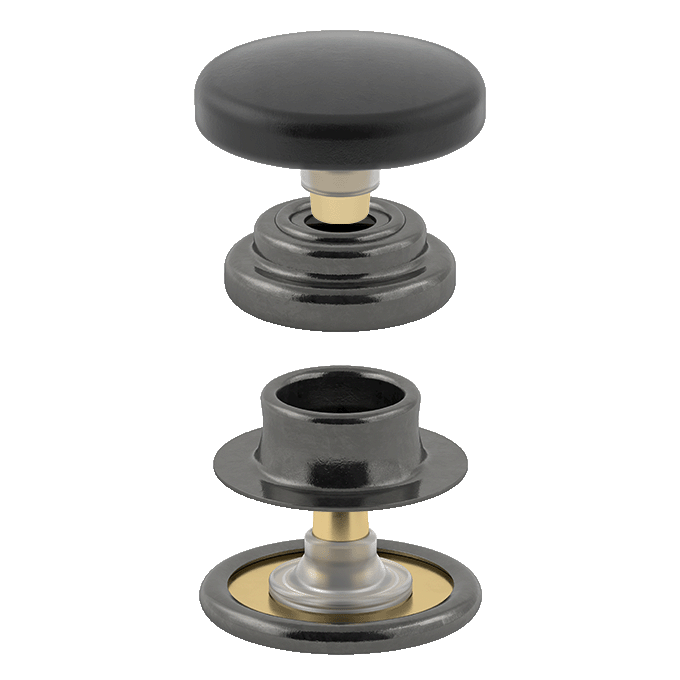

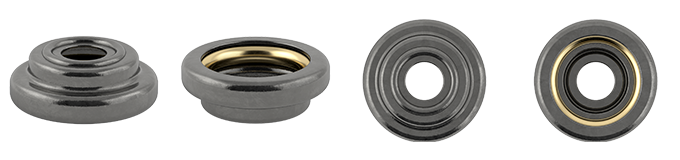

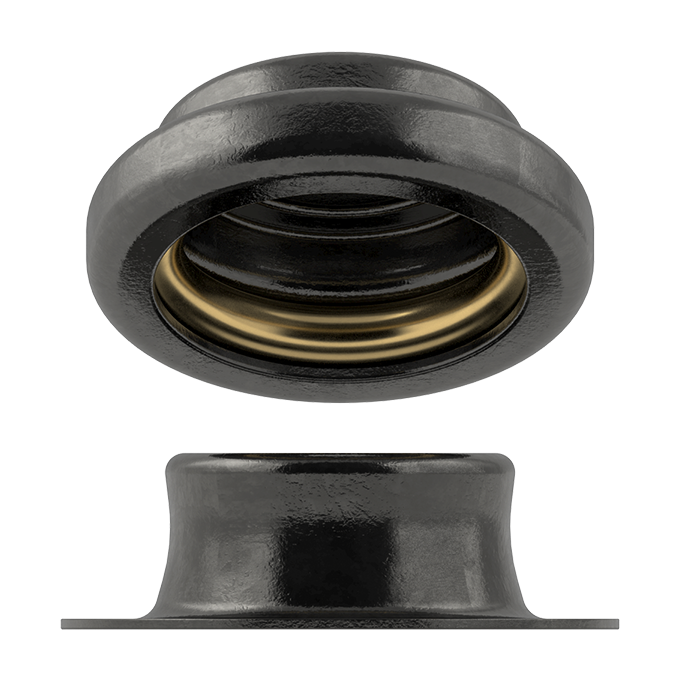

Product code DUR 4

Material brass

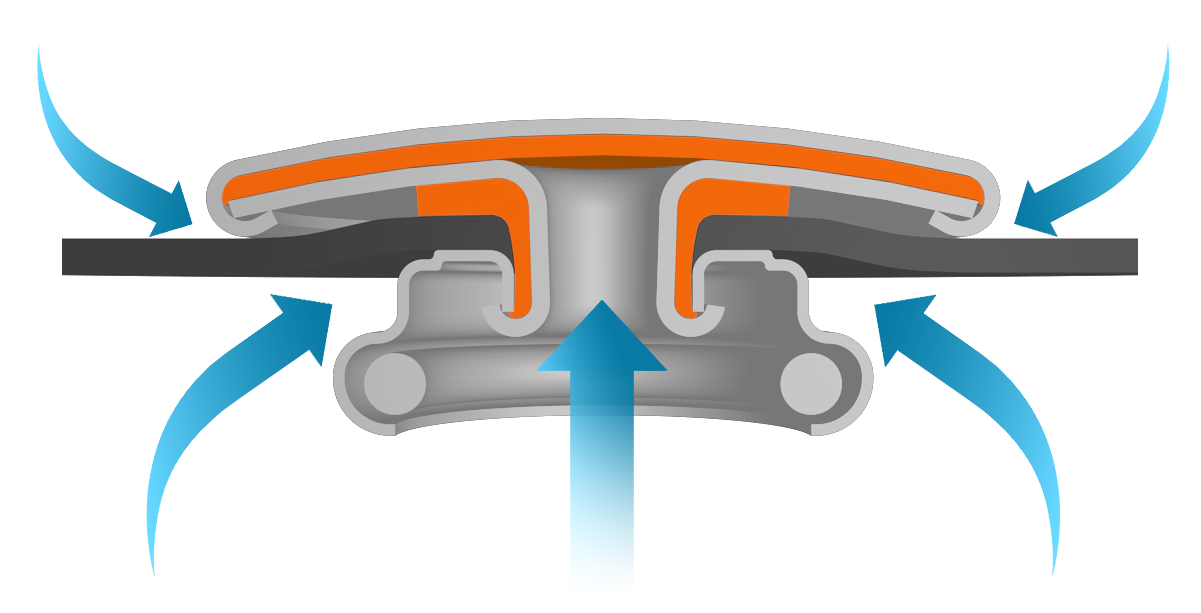

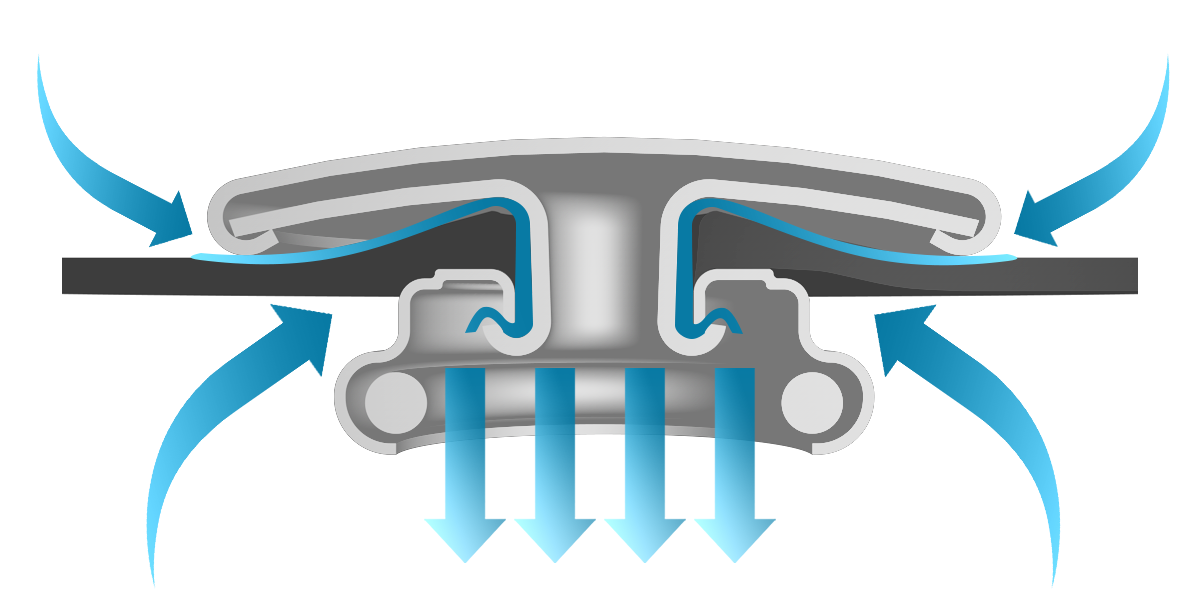

Robust waterproof ring spring system

Push-button fastening system on a ring spring basis specially developed for waterproof applications and waterproof laminates. Ideal for applications where waterproofness is required in addition to a high opening force and opening security (with side pull).

WetStop® is a proven fastening solution for rainwear and functional textiles for work, outdoor, ski, motorcycle and water sports and government clothing and equipment. The waterproof property also offers decisive advantages for many technical applications such as sports equipment, baby carriages, automotive, two-wheeler accessories and camping.

SPECIAL FEATURES

- Robust optics with WetStop® property

- High locking force

- Waterproof

- High opening forces

PROCESSING INSTRUCTIONS

- Suitable for many laminates and membranes – We are happy to test your material

- Semi-automatic application (see product catalog)

- Special stamp required for waterproof processing

TYPICAL AREAS OF APPLICATION

- Waterproof clothing for public authorities, work and sport

- Sports equipment

- Technical applications